EJKrueger – your innovative partner in extrusion

Willkommen bei EJK

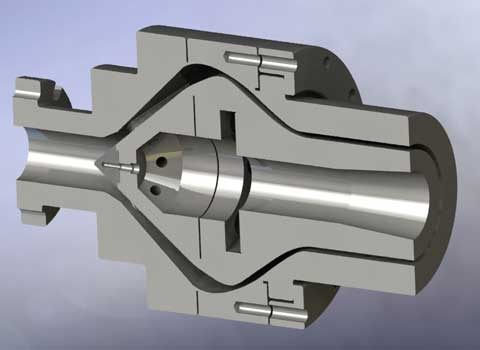

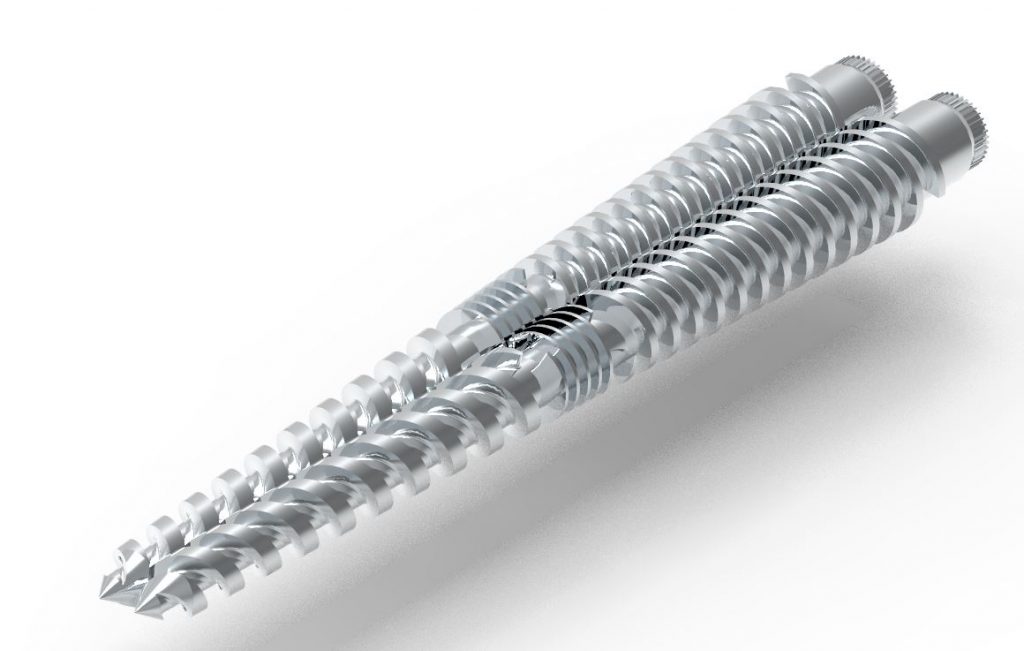

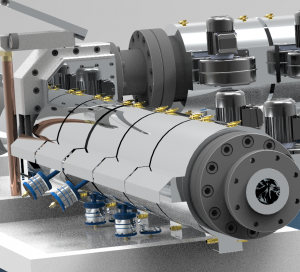

Die EJKrüger GmbH ist seit mehr als zwei Jahrzehnten im Bereich der Herstellung von Verfahrenseinheiten für die Kunststoffindustrie tätig. Während dieser Zeit wurde eine sehr große Anzahl an Verfahrensteilen für den Bereich der PVC-Verarbeitung ebenso wie der Verarbeitung von Polyolefinen oder Spezialkunststoffe gefertigt und an OEM in unterschiedlichsten Kontinenten geliefert. EJK fertigt insbesondere nach Zeichnungen, wobei auch gerne aus erfahrungsbedingter Modifikation in Kundenzeichnungen einfließen. Dieses betrifft insbesondere den Einsatz von unterschiedlichsten Werkstoffen und unterschiedlichsten Arten der Verschleißausrüstung. Hierbei sei nur erwähnt, dass Gegenläufer im Verhältnis zu Gleichläufern bzw. Einschnecken ein komplett anderes Verschleißverhalten und dementsprechend ein unterschiedlichen Verschleißschutz erhalten sollte.

Die OEM Struktur aus Asien, Middle East, Europa sowie Amerika erfordern unterschiedlichste Verfahrenseinheiten. EJK bedient diese OEM Struktur seit sehr langer Zeit und hat dort eine sehr langfristige und vertrauensvolle Zusammenarbeit aufgebaut.

Neben normalen Verfahrenseinheiten für die Extrusion und den Spritzguss werden verfahrenstechnische Maschinenbauelemente für unterschiedlichste Bereiche der Kunststoffverarbeitung hergestellt. Dieses ist insbesondere auch im Bereich der chemischen Industrie und dem Bereich der großen Verfahrenselemente. EJK kann Verfahrenselemente auch mit Einzelgewichten bis 15 Tonnen bearbeiten.

Sie können uns gerne direkt kontaktieren, jeden Tag von 8:00h bis 18:00h CET sind wir für Sie erreichbar unter +49 171 999 7777 oder unter info@ejkrueger.de.

Kontakt Informationen

EJKrueger GmbH

Schmiedestraße 28b

26629 Großefehn

Phone: +49 4943 9999 127

Mobile: +49 171 999 7777

Fax: +49 4943 9999 124

Email: info@ejkrueger.de