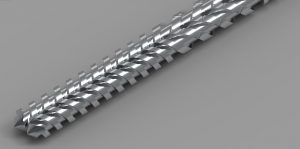

Counter rotating twin screws

EJK supplies counter-rotating twin screws for non-intermeshing and tightly intermeshing designs according to customer drawings.

Non-intermeshing, counter-rotating twin screws are usually made of special materials with wear-resistant screw surfaces. This wear protection is carried out in PTA as well as in laser process. The same category of non-intermeshing twin screws includes very large and long twin screws, which are operated at high speed in the field of granulate production.

In the case of the tightly intermeshing, counter-rotating twin screws, all sizes from a diameter of 35 mm upwards are manufactured both in conical and parallel versions. A large number of screws have been manufactured with length ratios of above L/D = 40. As standard all screws are deep drilled and provided with cooling. For this purpose, EJK has developed its own design of a closed-loop cooling system which is 100% maintenance free for over the lifetime of the screws.

- Maximum length 7,50m

- Max. diameter: 700mm

- Minimum diameter 35mm

The standard versions are usually supplied as gas nitrided versions. EJK supplies the running surface with a wear-protected design with wear material incorporated in the bed. This is usually a tungsten carbide version, but can also be provided with other wear protection materials according to customer requirements. On customer request, the screw channel can also be provided with a hard chrome coating, which was specially developed by EJK. This hard chrome layer has proven its worth both in tin formulations and in hard, abrasive applications with a high proportion of glass fibres.

On request, screws can also be coated with a complete tungsten carbide layer.